Capabilities

CAD

DiGesare Mechanical can provide a wide array of CAD services, from coordination drawings to fabrication drawings for piping, plumbing, fire protection and duct installations.

Our CAD designers have been involved with projects ranging from central chill plants for New York State University Campus to plumbing design for high-rise office buildings. We have taken mechanical room fabrication to the limit by designing and constructing an entire mechanical room on just four structural skids. The skids included three boilers, a plate and frame heat exchanger, several pumps, domestic water exchanger and all required accessories.

Project schedules can also benefit from the use of CAD. Customers no longer have to wait for bathroom plumbing to be installed. Bathroom groups can be designed and fabricated months before they are needed on site. Once delivered it is only a matter of several hours before a large bathroom group is installed and ready for inspection. By using this very proactive approach, critical dates are met or improved upon.

Duct and HVAC piping systems can also be designed months before it’s scheduled to be installed. Coordination issues can be worked out before the duct is ever built. Production of the duct can be properly scheduled and phased to fit the projects needs. The final design is down loaded directly to the computers controlling both the coil line, which manufacturers rectangular duct and the plasma tables, which cut out fittings.

By using highly trained people with frontline experience, we are able to efficiently achieve our ultimate goal, allowing DiGesare Mechanical, Inc. to perform at the highest possible level.

DESIGN & BUILD

We have an in-house design department as well as cad department to service our D/B projects. In most all cases we team with a mechanical consultant to perform the actual design development and construction drawings. Our D/B department as well as a dedicated principal from the consulting firm agree upon a concept and DMI executes the first stages of the conceptual engineering process – including all required conceptual estimating. At the point which the concept is approved, and the budget is established, we hand-off the design duties to the Mechanical Consultant. We have found this approach to be very efficient both financially and from a design perspective.

By using highly trained people with frontline experience, we are able to efficiently achieve our ultimate goal, allowing DiGesare Mechanical, Inc. to perform at the highest possible level.

Advantages to our Design Build approach:

Elimination of the value engineering process due to proper up-front communication.

Accurate conceptual estimates.

Oversight of an independent consulting firm.

More competitive fee structure as we perform much of the conceptual work in lieu of the consultant.

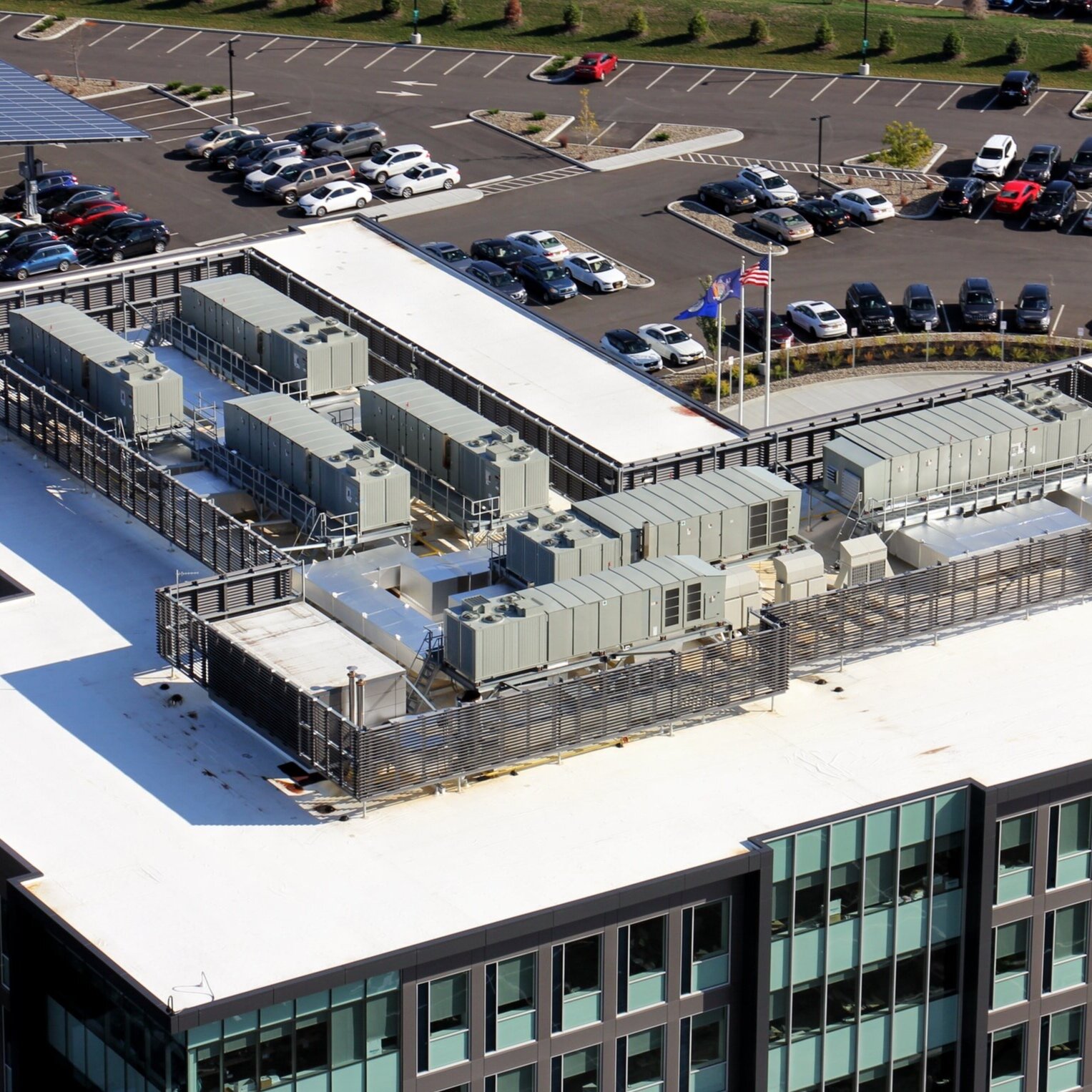

HVAC

We are proud to be the leading heating, ventilation and air conditioning contractor in the region. We perform work in virtually every market segment and project size. From air conditioning tenant improvements to high technology plants, high rise buildings to medical research facilities our experience is unmatched.

Our staff of trained professionals and field crews work closely to design, construct and install every type of sheet metal and piping imaginable for commercial, industrial, medical and manufacturing clients, big and small.

The HVAC industry is at the forefront of building comfort, energy management, safety, air quality and industrial processes. For many years DMI has proven its leadership to such clients as AT&T, KeyCorp, Albany International Felt Skidmore College and many others. Our reputation is based on quality and cost competitive installations and we are dedicated to that tradition.

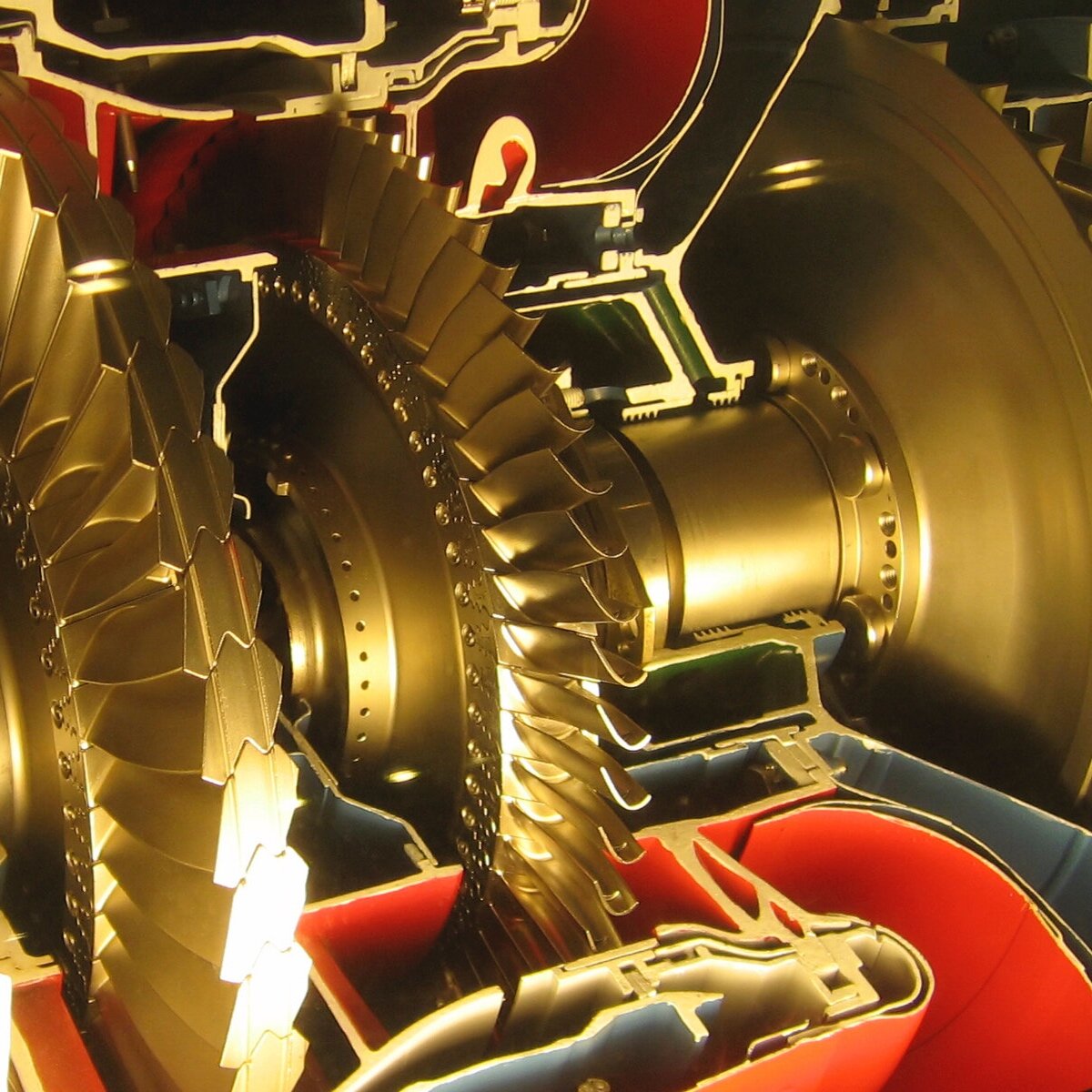

PLUMBING/PIPING

DiGesare Mechanical was built on a solid foundation: plumbing and piping. Clearly the dominant element of mechanical systems of that era, plumbing and piping are equally dynamic today. From sanitary and domestic water applications to process piping and chilled water systems, “piping” is an integral part of both mechanical systems and DiGesare Mechanical.

Our piping crews carry an extensive service background, providing boilers, chillers, cooling towers, and refrigeration systems to complement the sheet metal installation.

For more than five decades DiGesare has engineered, installed and maintained piping systems of every size and complexity. Our project experience is broad including hotels, office buildings, biotech laboratories, industrial plants, manufacturing facilities, hospitals and institutional buildings. From our fleet of service plumbing trucks to our crews for major projects, piping is our tradition. We are proud to have performed for the best: General Electric Global Research Center, Union College, Ellis Hospital, Albany Medical Center, Playtex, Ayesrst Laboratories and many others.

Employing as many as 150 piping craftsmen is only part of the story. DMI prides itself on its commitment to engineering focus, innovation and prefabrication in the installation, upgrades and maintenance of piping and plumbing systems. When our team is involved clients can be sure of proper applications, quality and cost effectiveness.

PREFABRICATION

DMI prides itself on maintaining one of the area’s best-tooled prefabrication facilities. Our shop which employs only ASME certified welders have at their disposal the latest in state of the art equipment, assuring fast and accurate piping assemblies. Whether the client’s issue is cost savings, job site restrictions, enhanced QA/QC, or the logistics of building design, our fabrication team is fully integrated into all phases of our business.

From maintaining schedules to manpower utilization, our fabrication capability is one of our key services. It has been DMI’s goal to pursue a more efficient approach to HVAC and Plumbing Piping Fabrication to compliment our experience in the field. The use of specialized computer software and sophisticated fabrication tools has helped us realize significant progress towards this end.

We have proven job after job that early planning and the use of prefabrication is fast, efficient and accurate, but also allows the client to be assured a superior finished installation.

PROJECT MANAGEMENT

The goal of DMI is to provide construction and project management services of the highest professional standard, and serve the needs of our clients in a superior manner. To achieve these goals we are committed to:

Completing our work in an efficient, workmanlike and quality manner the first time.

Maintaining and improving our reputation for fair treatment of Owners, Contractors, Consultants, Subcontractors and Suppliers.

Performing our work with continual concern for the safety of all involved.

Being the type of company that others respect and enjoy doing business with.

Executing our work with personal satisfaction and pride.

Each project is assigned a Project Manager which is either a principle of the company or backed by principle. The PM is responsible for all aspects of the project – that is, the mechanical construction, scheduling, cost and quality control. The PM has no other responsibilities beyond the successful completion of his/her assigned project. The PM brings the required expertise of the various phases to bear on the needs of the project. Our PM’s are well trained and are continually updated by attending classes and seminars held in-house and through industry associations. All PM’s and principles are college graduates in business, engineering, construction management or related degrees.